Products

Professional outside mutiple color sport court polyurethane floor paint

Polyurethane floor paint

Front

Reverse

Technical Parameters

| Property | Solvent free ( Water based ) |

| Repercussion value | ≥ 80% |

| Slip resistance | 60-80N |

| Damping property | 20-35% |

| Ground speed | 30-45 |

| Total thickness | 3 - 4mm |

| Mixed using time | <8 hours(25℃) |

| Touch drying time | 2h |

| Hard drying time | >24 h (25℃) |

| Service life | >8 years |

| paint colors | Mutiple color |

| Application tools | Roller,trowel,rake |

| Self time | 1 year |

| State | Liquid |

| Storage | 5-25 degree centigrade, cool, dry |

Application Guidelines

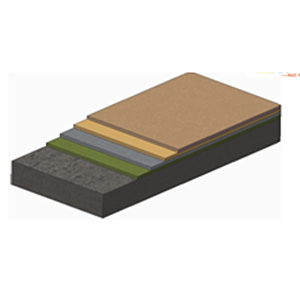

Pre-treated substrate

Primer

Middle coating

Top coating

Varnish (optionally)

| Application Scope | |

| Multifunctional and multipurpose elastic flooring paint system for indoor & outdoor professional sport court , tennis court, basketball court, volleyball court, running track,industrial plants, school, hospitals, public places, parking lots and public buildings etc. | |

| Package | |

| 20kg/barrel. | |

| Storage | |

| This product stored at above 0 ℃, well ventilation, shady and cool place. |

Application Instruction

Construction Conditions

The construction conditions should not be in moisture season with cold weather (temperature is ≥10℃ and humidity is ≤85%). The below application time refers to normal temperature in 25℃.

Application Step

Primer:

1. Put hardener into primer resin as 1:1 (primer resin:hardener=1:1 by weight).

2. Stir both components together for about 3-5 minutes until it is homogenous.

3. Apply the primer mixture using a brush, roller or spray gun at the recommended thickness of 100-150 microns.

4. Allow the primer to fully cure for at least 24 hours before proceeding to the next step.

Middle Coating:

1. Put hardener into middle coating resin as 5:1 (middle coating resin:hardener=5:1 by weight).

2. Stir both components together for about 3-5 minutes until it is homogenous.

3. Apply the middle coating using a roller or spray gun at the recommended thickness of 450-600 microns.

4. Allow the middle coating to fully cure for at least 24 hours before proceeding to the next step.

Top Coating:

1. Put hardener into top coating resin as 5:1 (top coating resin:hardener=5:1 by weight).

2. Stir both components together for about 3-5 minutes until it is homogenous.

3. Apply the top coat using a roller or spray gun at the recommended thickness of 100-150 microns.

4. Allow the top coating to fully cure for at least three to seven days before using the area.

Notes

1. Use protective equipment such as gloves, goggles, and a respirator when handling the paint.

2. The ratio and mixing time for each component should be followed strictly.

3. Apply each layer in well-ventilated areas and avoid applying in direct sunlight.

4. Proper cleaning of the surface is necessary before applying the primer.

5. Over-application or under-application of the paint might lead to issues with the finish, so follow the recommended thickness guidelines.

6. The curing time of each layer may vary depending on the temperature and humidity of the area, so it is best to observe the surface until it is fully cured.

Conclusion

Applying sport court polyurethane floor paint is a straightforward process that requires attention to detail and proper adherence to the conditions and steps outlined above. A properly constructed surface can provide long-lasting durability and resistance to wear and tear. We hope that this guide provides a clear idea of the application process for sport court polyurethane floor paint, which can help achieve your desired result for your sports facilities or multipurpose areas.