Products

Long service life texture natural stone paint for exterior walls

Natural stone paint

Front

Reverse

Technical Parameters

| Primer | Natural Stone Top Coating | Varnish (optional) | |

| Property | Solvent free ( Water based ) | Solvent free ( Water based ) | Solvent free ( Water based ) |

| Dry film thickness | 50μm-80μm/layer | 2mm-3mm/layer | 50μm-80μm/layer |

| Theoretical coverage | 0.15 kg/㎡ | 3.0 kg/㎡ | 0.12 kg/㎡ |

| Touch dry | <2h(25℃) | <12h(25℃) | <2h(25℃) |

| Drying time (hard) | 24hours | 48hours | 24hours |

| Volume solids % | 60 | 85 | 65 |

| Application restrictions Min. Temp. Max. RH% |

(-10) ~ (80) | (-10) ~ (80) | (-10) ~ (80) |

| Flash point | 28 | 38 | 32 |

| State in the container | After stirring, there is no caking, showing a uniform state | After stirring, there is no caking, showing a uniform state | After stirring, there is no caking, showing a uniform state |

| Constructability | No difficulty in spraying | No difficulty in spraying | No difficulty in spraying |

| Nozzle orifice (mm) | 1.5-2.0 | 6-6.5 | 1.5-2.0 |

| Nozzle pressure(Mpa) | 0.2-0.5 | 0.5-0.8 | 0.1-0.2 |

| Water resistance(96h) | Normal | Normal | Normal |

| Acid resistance (48h) | Normal | Normal | Normal |

| Alkali resistance(48h) | Normal | Normal | Normal |

| Yellowing resistance (168h) | ≤3.0 | ≤3.0 | ≤3.0 |

| Wash resistance | 3000 times | 3000 times | 3000 times |

| Tarnish resistance /% | ≤15 | ≤15 | ≤15 |

| Mixing ratio for water | 5%-10% | 5%-10% | 5%-10% |

| Service life | >15 years | >15 years | >15 years |

| Storage time | 1 year | 1 year | 1 year |

| Coatings colors | Multi-color | Single | Transparent |

| Application way | Roller or Spray | Roller or Spray | Roller or Spray |

| Storage | 5-30℃, cool, dry | 5-30℃, cool, dry | 5-30℃, cool, dry |

Application Guidelines

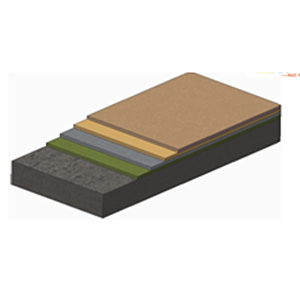

Pre-treated substrate

Filler (optional)

Primer

Marble texture top coating

Varnish (optional)

| Application |

|

| Suitable for commercial building, civil building, office, hotel, school, hospital , apartments, villa and other exterior and interior walls surface decoration and the protection. | |

| Package | |

| 20kg/barrel. | |

| Storage | |

| This product stored at above 0 ℃, well ventilation, shady and cool place. |

Application Instruction

Construction Conditions

Before starting the project, it is essential to take into account the weather conditions. The ideal temperature range for application is between 10°C to 35°C, with relative humidity no higher than 85%. The surface temperature should be at least 5°C above the dew point. If the surface is wet or damp, wait until it is dry before applying the paint.

Application Step

Surface preparation :

To begin with, the first step is to assess the surface area and determine the amount of paint required to cover it. This will depend on how porous the surface is and the desired thickness of the paint coat. It is essential to ensure the surface is clean and free of any dirt or debris.

Primer :

Once the surface is clean, the next step is to apply the primer to the surface. The primer not only covers up any defects or inconsistencies in the surface but also provides a level of adhesion for the natural stone paint. The primer can be applied using a brush, roller or spray gun, in accordance with the manufacturer's instructions, and should be allowed to dry for a set period, usually around 24 hours. The primer will penetrate into the surface, providing a sound surface for the natural stone paint to adhere to when applied.

Natural stone top coating :

After the primer has dried, it is time to apply the natural stone paint topcoat. This can be done with the use of a brush, roller or spray gun, depending on the size of the area to be covered. It is important to make sure the natural stone paint is uniformly applied and covers any areas that are missed with the primer. The natural stone paint should be applied using even coats to ensure full coverage, and each coat should be allowed to dry before the next layer is added.

It is essential to note that the quality of the final finish depends on the skill of the painter. Therefore, it is essential to take the time to paint the surface evenly, allowing the paint to dry fully before applying the next coat. The recommended thickness of the natural stone paint topcoat is typically around 2mm to 3mm.

Natural stone paint topcoating requires careful application to achieve the best results. A Primer is essential to create a sound surface for the topcoat to adhere to and should be applied in accordance with the manufacturer's instructions. The natural stone paint topcoat should be applied in even coats to ensure full coverage, and each coat should be allowed to dry before applying the next layer. A well-executed natural stone paint topcoat will transform any surface, giving it a natural, textured finish that is durable and long-lasting.

Cautions

When applying the natural stone topcoat, make sure that you do not apply too thick of a layer. If the coat is too thick, it may sag or crack when it dries out. Additionally, it is essential to avoid applying the paint in direct sunlight or high winds, which can cause the paint to dry out too quickly.

Clean up

After the final coat is dry, it is vital to clean up all the tools and equipment to prevent the paint from drying or curing on them. Use soapy water to clean the paint rollers, brushes, and other tools. Dispose of the waste materials according to the local regulations.

Notes

While natural stone paint is relatively easy to apply, it is essential to remember that the final appearance will depend on the skill of the painter and environmental factors such as wind and humidity. Therefore, it is essential to take the necessary precautions, follow the manufacturer's recommendations, and take your time to ensure the best results.

In conclusion, applying natural stone paint to your exterior walls can give your home a beautiful and unique appearance. By following the construction conditions, application steps, cautions, clean-up procedures, and notes, you can ensure excellent results.